Tools for economic production

Kyocera at EMO Milano 2003 (21 – 28 October 2003)

03 October 2003

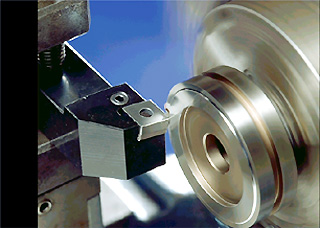

Quality chip removal tools and components made of technical ceramics and of what are known as ‘advanced materials’, such as Cermets, ceramics, silicon nitride, CBN and PCD, are presented by Kyocera Fineceramics GmbH at EMO Milano in Milan in hall 16/2, stand A27 from 21 to 28 October 2003.

The real innovation presented by the manufacturer of standard and customised cutting tools for the metalworking industry will be a new, effective tool system specially designed for moulding and die construction. The three-geared MEC Hurricane drill groove milling cutter is a tool with excellent chip removal and very low heat production during the process. At the same time, Kyocera will be exhibiting its wide range of cutting tools and tool systems. For all its products, the manufacturer sets great store by solutions which enable effective, economic production. The fracture-proof MEC Hurricane Endmill tool system is specially designed for steel processing and the processing of cast iron materials. Numerous technical improvements make the production process much more effective when using this system. The large chipping angle of maximum 23 degrees means that the cutting force is lower than that of conventional products and no heat is developed during the production process. The MEC Hurricane drill groove milling cutter also has excellent chip extraction as a result of an enhanced chip groove geometry. The stability and service life have been optimised thanks to

the special tool holder construction and plate fit and the special coating to protect the carrier tool from corrosion. What sets the system apart is its excellent chipping performance and the special design of its cutting edge. This is thanks to the new cutting material, PR830. The feed rate can be doubled. This sheds light on another advantage: Even at the higher feed rate, the system generates less noise and fewer vibrations.

As well as the new system, Kyocera will be presenting a wide range of tools, tool systems and cutting materials at EMO Milano – from indexable inserts and advanced materials to compound ceramics with special coatings.

the special tool holder construction and plate fit and the special coating to protect the carrier tool from corrosion. What sets the system apart is its excellent chipping performance and the special design of its cutting edge. This is thanks to the new cutting material, PR830. The feed rate can be doubled. This sheds light on another advantage: Even at the higher feed rate, the system generates less noise and fewer vibrations.

As well as the new system, Kyocera will be presenting a wide range of tools, tool systems and cutting materials at EMO Milano – from indexable inserts and advanced materials to compound ceramics with special coatings.

About Kyocera Cutting Tools:

Headquartered in Kyoto, the Kyocera Corporation is a technology group with many years of experience in the field of tool production for the metalworking industry. The company has special know-how in the manufacturing of quality cutting tools and coatings. Particular emphasis is placed on tools in the field of what are known as “advanced materials”, such as Cermets, ceramics, silicon nitride, CBN and PCD. The group is the world’s leading supplier of the cutting material Cermet. All Kyocera’s tools and tool systems are tailored to the customer’s individual requirements and are used in general mechanical engineering, the automobile and automotive supply industries and in tool and mould construction.